Helping manufacturers become competitive by Reducing Energy Usage, Wastage, Carbon Footprint.

About Us

Our mission is to help manufacturers become competitive by Reducing Energy Usage, Wastage, Carbon Footprint and become Socially Responsible while making a world a Greener Place.

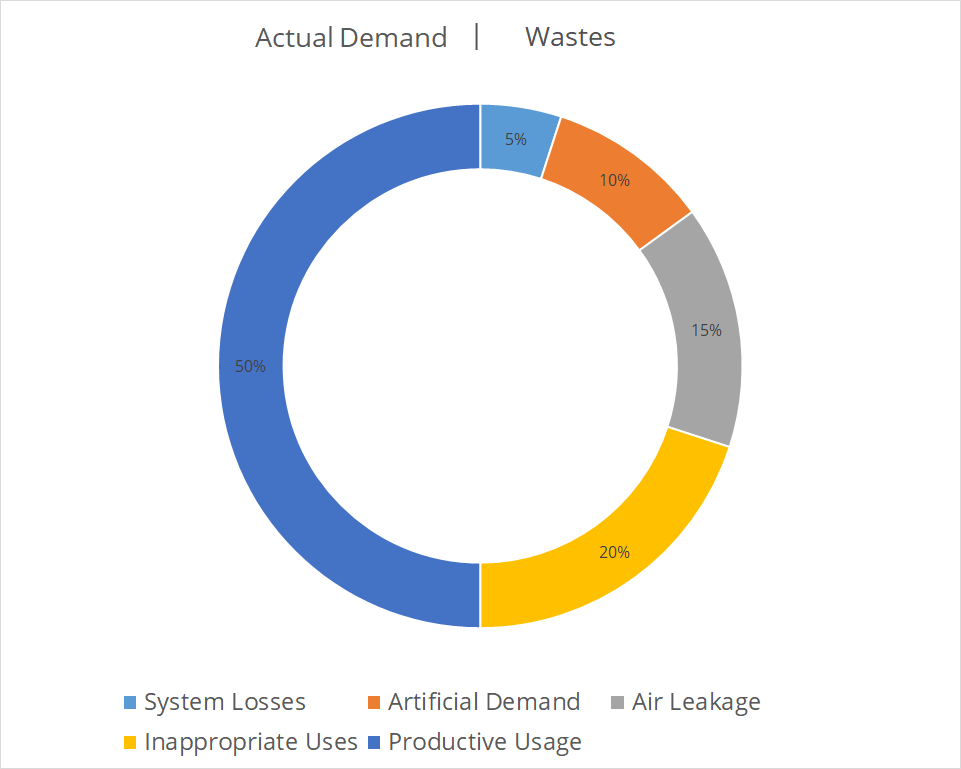

Air Audit help its customers in identifying opportunities for reducing energy consumption and overall business costs of their Compressed air installations. If a business is a user of compressed air, An Air Audit is a step to make a substantial impact on its production costs. It can make entire business performance to high level, not just once, but year after year.Air Audit identifies inefficiencies in compressed air system and assists with entire system performance

optimization, leak deduction, reduction and practical air management processes. It helps customers reduce power consumption and also reduce compressed air system load and wear and tear. This prolongs life of entire compressed air system.optimization, leak deduction, reduction and practical air management processes. It helps customers reduce power consumption and also reduce compressed air system load and wear and tear. This prolongs life of entire compressed air system.

Why Air Audit of compressed air system is required?

Air Audit is an accurate process undertaken to identify areas of loss or inefficiencies within a compressed air system. Air Audit is performed by trained audit engineers with experience in identifying and rectifying compressed air system faults and inefficiencies, using non intrusive state of the equipment.

Air Audit provides detailed independently assessed and compiled reports providing information on :

- System optimization

- Distribution

- Risk assessment

- Cost savings

- Recommendations

- Conclusions

- Ongoing energy management plans

Air Audit is an accurate and totally non intrusive process that has been developed to help your business.