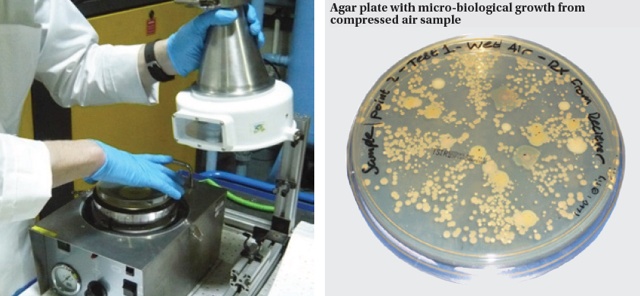

Did you know that microorganisms thrive in moist, humid environments – environments that can be created by compressing atmospheric air? This means that in industries like food and beverage (were clean and dry compressed air is particularly essential), it’s necessary to eliminate the conditions that permit microorganism growth, thereby reducing the risk of microorganism growth in the final product.

All microorganisms require five factors to remain viable and reproduce: nutrients, proper pH, gases, temperatures, and moisture. However, nutrients, the proper pH, and gases aren’t impacted by the air in the compression process; this means that only temperature and moisture can be directly linked to/impacted by air compression.

Temperature

Every microorganism has its own heat tolerance, though heat is normally lethal to these organisms. In oil-free compressors, the high temperature in oil-free compression elements (>180°C or 356°F) is typically high enough to significantly reduce the presence of microorganisms.

Moisture

Like with temperature, the amount of moisture needed for microorganism growth varies per organism. With that said, a relative humidity level of 75% or above is typically needed for growth, and a relative humidity level of 50% or less usually results in little to no microorganism proliferation. A key target to shoot for is between 10% and 20% relative humidity to inhibit growth altogether.

Contact AirAudit for consultation regarding everything about compressed air system:

📞 +92 310 562 3329 ; +92 322 821 0271

📧 info@airaudit.com.pk