Why Air Audit of compressed air system is required?

Air Audit is an accurate process undertaken to identify areas of loss or inefficiencies within a compressed air system. Air Audit is performed by trained audit engineers with experience in identifying and rectifying compressed air system faults and inefficiencies, using non intrusive state of the equipment.

Air Audit provides detailed independently assessed and compiled reports providing information on :

- System optimization

- Distribution

- Risk assessment

- Cost savings

- Recommendations

- Conclusions

- Ongoing energy management plans

Air Audit is an accurate and totally non intrusive process that has been developed to help your business.

Why do you need an Air Audit?

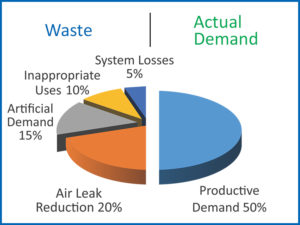

A compressed air audit can provide you opportunities to increase your production while at the same time reduce operating costs. Although it is basically a numbers game, the idea is that an audit should be able to identify and teach you if there are options available. For example, leaks are the most common problem identified and can cost you a lot than you probably know. You can save money by making sure that you minimize or avoid inappropriate uses.