An Air Audit can pin point wastages in your Compressed Air System

Compressed air systems are used extensively in Textile industry to provide compressed air for processes ranging from spinning, weaving, hosiery, dyeing etc. There are also several compressed air uses in industry that in most cases can be considered misuses, which includes applications such as product cooling and cleaning.

It’s about taking compressed air, looking at it as your fourth utility, and making compressed air as dependable as your electric, water and gas services.

Plant Air Audit: What’s In It For You?

It’s about taking compressed air, looking at it as your fourth utility, and making compressed air as dependable as your electric, water and gas services. The challenges associated with operating a modern compressed air system are fairly complex and often camouflaged to the untrained eye. At the same time, many companies lack the internal resources trained to define and solve those problems. That’s where a professional Air Audit can help by addressing the total process of producing compressed air… not just the compressors

A well-conducted audit of your compressed air system provides you with the only sure way to bring down your compressed air related manufacturing costs and manage the often mysterious workings of your air system.

Benefits of a Compressed Air System Audit

Audits provide the most accurate possible data on the current system conditions to help manage the system to identify component upgrades and ensure the entire system operates as it should. An audit can help plant management to Reduce compressed air costs.

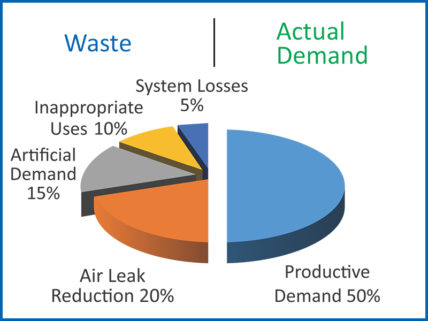

Compressed Air Demand and Wastes

- Reduce maintenance costs by 10% to 80%.

- Get accurate data on current system conditions and machine health.

- Receive documentation on power usage.

- Air Audit can be conducted without downtime or disruption to productivity.

- Reduced capital spending

- Improved manufacturing productivity

Air Quality for Textile Manufacturer

| Sustained Health of the System Requires

|

Optimize Compressed Air System to Turn Off Compressors

Air Audits help plant operators optimize their systems and often result in turning off compressors! This may sound crazy, but it’s true. In the past customers asked compressor manufacturers, like CompAir, to build the best engineered, most reliable, energy-efficient air compressors in the industry. But in today’s global business climate, you need more than great equipment to survive and thrive. To drive operational excellence we must go beyond the components of an air system and find solutions to the operating issues every air consumer faces.

Compressed air system problems require total solutions. A professionally conducted Air Audit help you define system problems, whether they are in demand, distribution or supply, allowing you to develop cost-efficient solutions that meet your return on investment goals.

Keeping Compressed Air Lines Dry

Compressed Air System is, traditionally, installed with water grade galvanized iron piping and plumbing fittings, without taking into consideration the host of design factors which affect its efficiency. GI Pipe loses its coating where it is threaded, but this is the area where rust proofing is most important. Thus, within three years, most systems are losing up to 30% of compressed air through leaks at the threaded joints. Furthermore, there is no leak inspection in most plants. Regular checkups are usually not performed, to discover leakages in piping as well as the machines using compressed air. The results are deteriorating performance over a period of time. Air Audit highlights system failures that may otherwise not be detectable and may silently be increasing yearly expenses on energy.