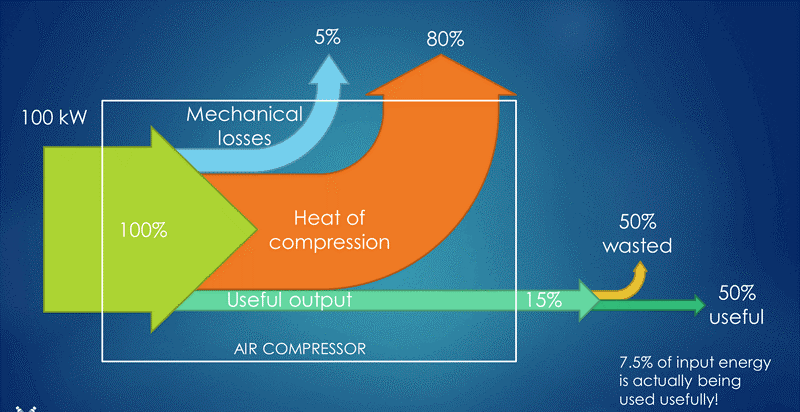

The physics of compressed air dictates that heat must be generated if air is compressed. The amount of heat depends on the size of the compressor. For example, a fully loaded 25 hp compressor will produce more than 63,000 Btu/hr of heat—if you do the math, this is the equivalent to about 18 kW of power.

Isn’t 18 kW equivalent to 25 hp? Yes it is, this means almost all the energy that goes into an air compressor comes out as heat. That’s why powering tools and equipment with compressed air is so expensive.

The problem with air compressors is that designers usually close them into a small room because they are so noisy (some newer compressors are not so noisy). A number of compressors might be squeezed into a small space to save valuable floor space. And because ventilation ducting is expensive, there might only be an inadequately sized ventilation hole cut into the wall to cool the room.

Compressors with no ducting will exhaust into the room, heating up the space if there is not adequate air flow—both into and out of the room. In the worst case scenario, the compressor cooling fan will suck in already heated air to form a closed circuit that will quickly cause compressor overheating. Compressor room ventilation must direct the heat of compression away from the cooling air inlet, so problems do not occur. And don’t forget about the auxiliary equipment like refrigerated air dryers—these also create heat that can cause higher than desired compressor room temperatures.

If you live in a cooler climate, the heat of compression can be used for a secondary purpose like displacing building heat. Often, the compressor ducting can be modified with a summer/winter position so that the heat can be captured in winter to lower your heating bills. Heat of compression can also be used for other things like heating water or glycol, boiler pre-heat, drying of objects etc.

A good test for temperature is to measure the discharge of the compressor with an infrared gun; if more than 100° F, you have reason to be concerned. If you don’t have a gun feel the discharge with you hand, if it feels uncomfortably hot then there may be a problem. The key goal is to keep the temperature in the compressor room as cool as possible, but not below freezing. Compressors perform better at cooler temperatures. Key to cooling is to keep the compressor air discharge temperature lower than the rating of any air dryers. Air dryers are typically rated at about 100° F inlet temperature. If ambient temperatures are such that this is not possible, then secondary cooling may be required, or oversized air dryer designed to compensate for the increased moisture loading that comes with higher compressed air temperatures.