Compressed Air Flow Monitoring: Why It Matters for Every Industrial Facility

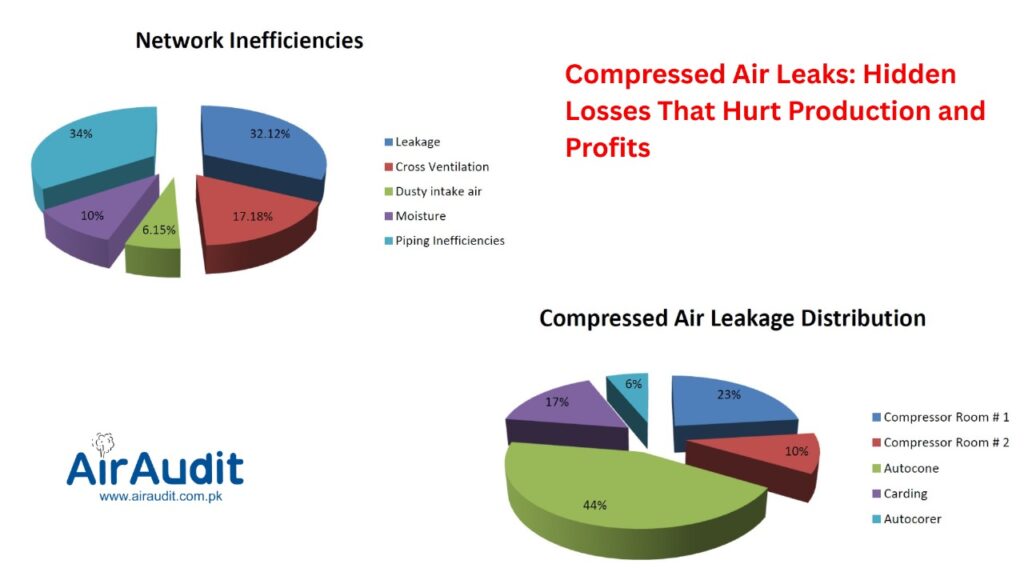

Compressed air is one of the most expensive utilities in any plant — yet it’s also one of the most wasted. This is where compressed air flow monitoring becomes essential. By measuring real-time air consumption, flow monitoring gives you complete visibility into how your system is performing. One of the biggest benefits is energy efficiency. […]

Compressed Air Flow Monitoring: Why It Matters for Every Industrial Facility Read More »